In an era where efficiency and adaptability are critical, innovations in water treatment and bottling are leading the charge. Specifically, RO plants, RO filling machines, and ozone generators are revolutionizing the water bottling industry by enhancing both the quality and operational efficiency of water production processes. Let’s dive into how these advanced technologies are reshaping the industry landscape.

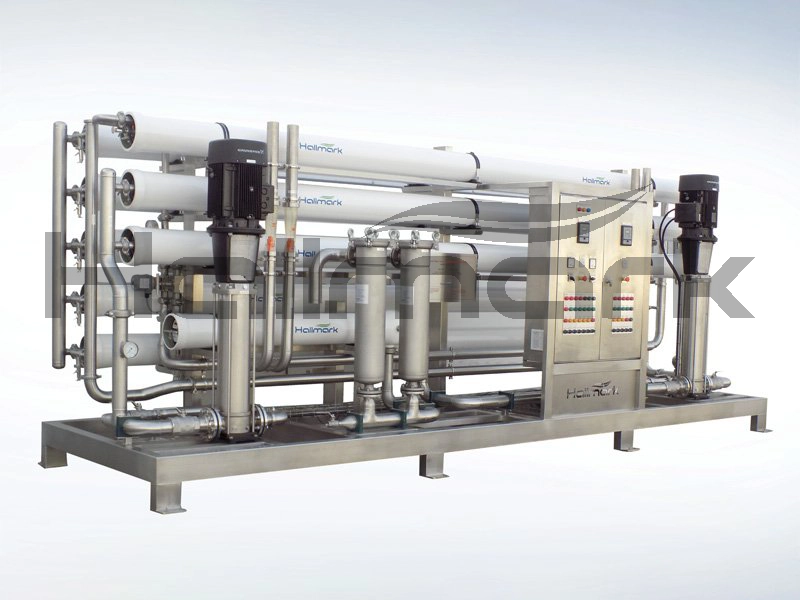

RO Plants: Precision and Purity

Reverse Osmosis (RO) plants are at the forefront of water purification technology. Designed to remove impurities, contaminants, and dissolved solids from water, RO plants ensure that the end product is of the highest purity. Their effectiveness in producing clean, safe drinking water has made them a cornerstone of the water bottling industry.

RO plants are versatile and scalable, making them suitable for a range of applications, from small-scale operations to large bottling facilities. Their modular design allows for easy expansion and customization, ensuring that the system can grow in tandem with production needs. Additionally, RO plants are efficient, using advanced filtration membranes and high-pressure pumps to deliver consistent quality while minimizing waste.

RO Filling Machines: Efficiency in Action

Once the water has been purified, the next step is filling it into bottles—a process that must be both precise and rapid. RO filling machines are engineered to streamline this crucial phase of the bottling process. These machines are designed for high-speed operation, capable of filling large volumes of bottles with minimal manual intervention.

RO filling machines come equipped with advanced features such as automatic capping, labeling, and quality control checks. Their precision ensures that each bottle is filled to the correct level, reducing spillage and ensuring consistent product quality. The integration of these machines into the production line enhances efficiency, reduces labor costs, and boosts overall throughput, making them indispensable for modern bottling operations.

Ozone Generators: Purification Beyond Filtration

In addition to RO plants and filling machines, ozone generators are playing a pivotal role in the water bottling industry. Ozone, a powerful oxidizing agent, is used to disinfect and purify water by breaking down organic contaminants and killing microorganisms. Ozone generators offer a chemical-free alternative to traditional disinfection methods, ensuring that water is treated to the highest standards without leaving harmful residues.

These generators are particularly valuable in maintaining the quality and safety of bottled water. They are capable of treating water at various stages of the bottling process, from pre-treatment to final disinfection, providing an additional layer of protection. Ozone generators are also effective in extending the shelf life of bottled water by reducing the risk of microbial growth and contamination.

Transforming the Water Bottling Industry

The integration of RO plants, RO filling machines, and ozone generators is transforming the water bottling industry by combining advanced filtration, efficient filling, and cutting-edge disinfection technologies. This synergy enhances product quality, operational efficiency, and safety, ensuring that consumers receive clean and reliable bottled water.

RO Plants deliver the highest purity through advanced filtration, RO Filling Machines streamline the bottling process with precision and speed, and Ozone Generators provide additional purification and safety. Together, these technologies are setting new standards in the water bottling industry, meeting the increasing demand for high-quality water products while optimizing production processes.

Embrace the future of water bottling with these innovative solutions and explore the possibilities they bring to achieving excellence in water quality and operational efficiency.